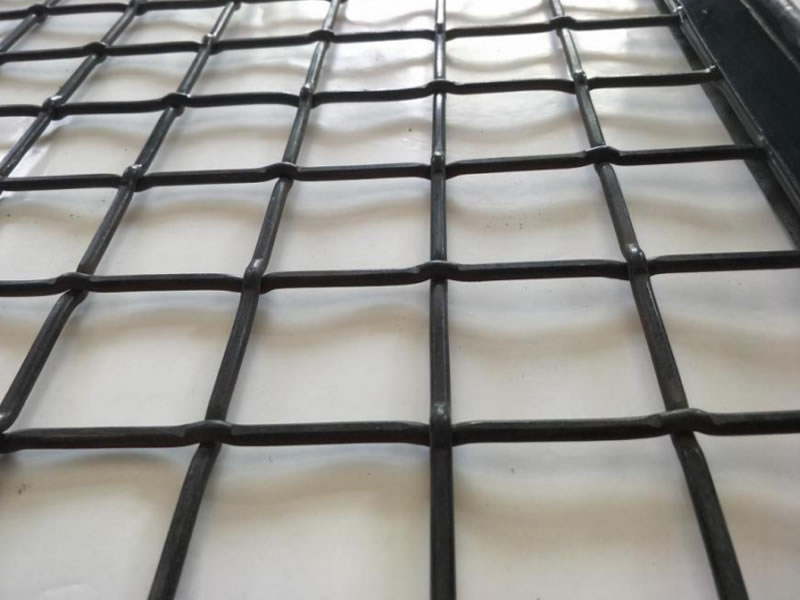

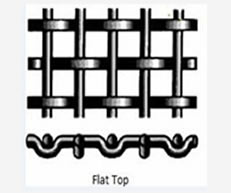

Flat top woven wire screen material:

Carbon steel wire;

manganese steel wire;

stainless steel wire.

The material parameter is as following:

High Carbon steel Parameter:

NO | Grade | Chemical Composition | Strength Property | ||

| C | Si | Mn | σb (MPa) | ||

| 1 | 30Mn | 0.27-0.34% | 0.17-0.37% | 0.70-1.00% | 540 |

| 2 | 45 | 0.42-0.50% | 0.17-0.37% | 0.50-0.80% | 600 |

| 3 | 50 | 0.47-0.55% | 0.17-0.37% | 0.50-0.80% | 630 |

| 4 | 55 | 0.52-0.60% | 0.17-0.37% | 0.50-0.80% | 645 |

| 5 | 60 | 0.57-0.65% | 0.17-0.37% | 0.50-0.80% | 675 |

| 6 | 65 | 0.62-0.70% | 0.17-0.37% | 0.50-0.80% | 695 |

| 7 | 70 | 0.67-0.75% | 0.17-0.37% | 0.50-0.80% | 715 |

| 8 | 65Mn | 0.62-0.70% | 0.17-0.37% | 0.90-1.20% | 980 |

| 9 | 72A | 0.69-0.76% | 0.15-0.35% | 0.30-0.60% | 1570 |

Stainless Steel Parameter:

NO | Grade | Chemical Composition | Strength Property | |||

| C | Ni | Mn | Cr | σb (MPa) | ||

| 1 | 202 | ≤0.15% | 4.0-6.0% | ≤7.5% | 17.0-19.0 | 520 |

| 2 | 304 | ≤0.08% | 8.0-10.5% | ≤2.0% | 18.0-20.0 | 520 |

| 3 | 321 | ≤0.08% | 9.0-12.0% | ≤2.0% | 17.0-19.0 | 520 |

| 4 | 316 | ≤0.08% | 10.0-14.0% | ≤2.0% | 16.0-18.5 | 520 |

Wire diameter: 0.71mm - 12.5mm.

Mesh size: 1mm - 100mm.

Specifications:

Hole size (mm) | Light Types | Middle Types | Heavy types | |||

| Wire diameter (mm) | Opening Rate % | Wire diameter (mm) | Opening Rate % | Wire diameter (mm) | Opening Rate % | |

| 125.0 | — | — | 10.00 | 86 | 12.5 | 83 |

| 112.0 | — | — | 10.00 | 84 | 12.5 | 81 |

| 100.0 | — | — | 10.00 | 83 | 12.5 | 79 |

| 90.0 | — | — | 10.00 | 81 | 12.5 | 77 |

| 80.0 | — | — | 10.00 | 79 | 12.5 | 75 |

| 71.0 | — | — | 10.00 | 77 | 12.5 | 72 |

| 63.0 | 8.00 | 79 | 10.00 | 74 | 12.5 | 70 |

| 56.0 | 8.00 | 77 | 10.00 | 72 | 12.5 | 67 |

| 50.0 | 6.50 | 79 | 8.00 | 74 | 10.00 | 69 |

| 45.0 | 6.50 | 77 | 8.00 | 72 | 10.00 | 67 |

| 40.0 | 6.50 | 75 | 8.00 | 69 | 10.00 | 64 |

| 36.0 | 5.00 | 77 | 6.50 | 72 | 8.00 | 67 |

| 32.0 | 5.00 | 75 | 6.50 | 70 | 8.00 | 64 |

| 28.0 | 5.00 | 72 | 6.50 | 67 | 8.00 | 60 |

| 25.0 | 5.00 | 69 | 6.50 | 64 | 8.00 | 57 |

| 22.0 | 4.00 | 72 | 5.00 | 66 | 6.30 | 60 |

| 20.0 | 4.00 | 69 | 5.00 | 64 | 6.30 | 58 |

| 18.0 | 4.00 | 67 | 5.00 | 61 | 6.30 | 55 |

| 16.0 | 3.00 | 70 | 4.00 | 64 | 5.00 | 58 |

| 14.0 | 3.00 | 67 | 4.00 | 60 | 5.00 | 54 |

| 13.0 | 3.00 | 65 | 4.00 | 58 | 5.00 | 52 |

| 11.0 | 2.50 | 67 | 3.00 | 61 | 4.00 | 54 |

| 10.0 | 2.50 | 64 | 3.00 | 58 | 4.00 | 51 |

| 9.0 | 2.50 | 61 | 3.00 | 55 | 4.00 | 48 |

| 8.0 | 2.00 | 64 | 2.50 | 58 | 3.00 | 51 |

| 7.0 | 2.00 | 61 | 2.50 | 55 | 3.00 | 48 |

| 6.0 | 2.00 | 56 | 2.50 | 50 | 3.00 | 43 |

| 5.0 | 2.00 | 54 | 2.50 | 44 | 3.00 | 38 |

| 4.5 | 1.80 | 51 | 2.20 | 45 | 2.50 | 41 |

| 4.0 | 1.60 | 51 | 2.00 | 44 | 2.20 | 41 |

| 3.0 | 1.20 | 50 | 1.50 | 40 | 2.00 | 38 |

| 2.0 | 0.80 | 50 | 1.20 | 41 | 1.50 | 40 |

| PS: Other hole size and wire diameter to match, clients can require. | ||||||

Application:

Mainly used as screen mesh, it is widely used in many industries, such as mining screen, quarrying screen, the screen deck, screen wire for stone crusher, Classifying Trommel; Vibrating screen; Road construction equipment; The Asphaltum mix round equipment and the mine vibrating screens, chemical industry, pharmacy, machinery, protection, construction.

Material:

High tensile screen cloth is commonly used in heavy duty applications for scalping and sizing of rocks,aggregates,limestone,etc.

They are weaved in sizes to suite most vibrating screens and available in:

* High Tensile Steel---Abrasion resistance

* Stainless Steel---Corrosion resistance

* Monel,Brass,etc---General applications

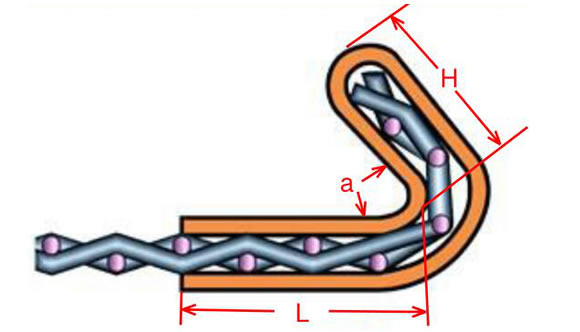

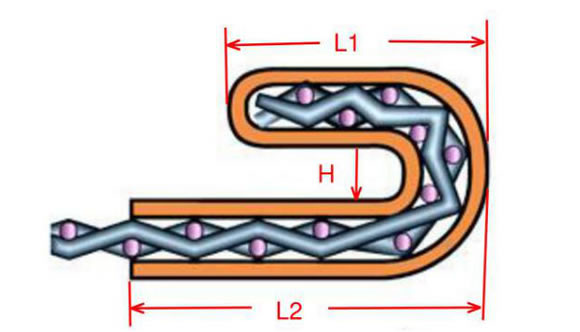

End Tension Reinforced Shroud Banded Edge

Specially reinforced to prevent pull-out under extreme screen tensioning. Also available in Double Reinforced Style. Plate thickness can be required.

Application:

Vibrating screens for primary sieving of mine and aggregates, as well as asphalt mixer plant in road building.