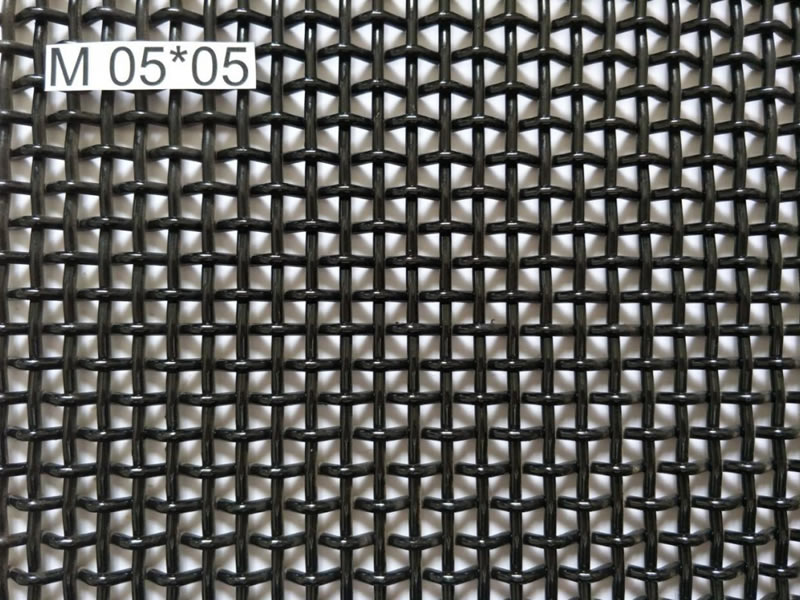

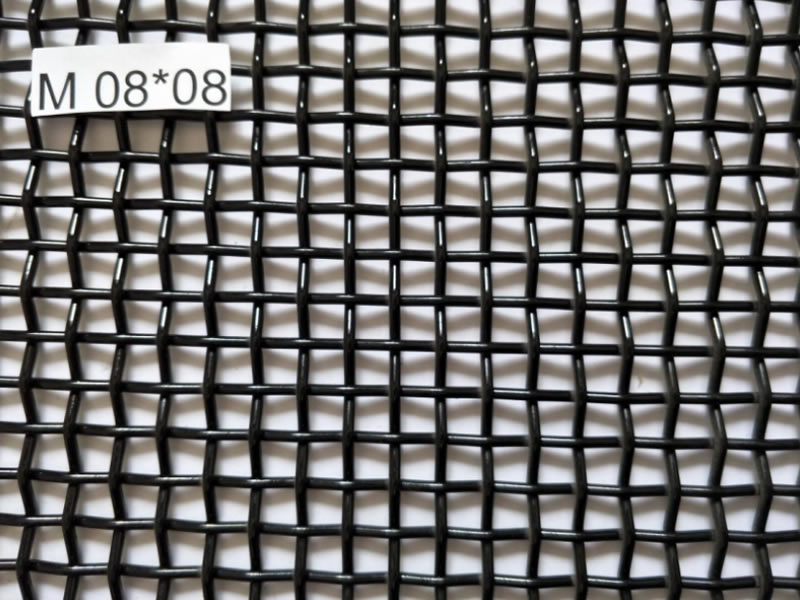

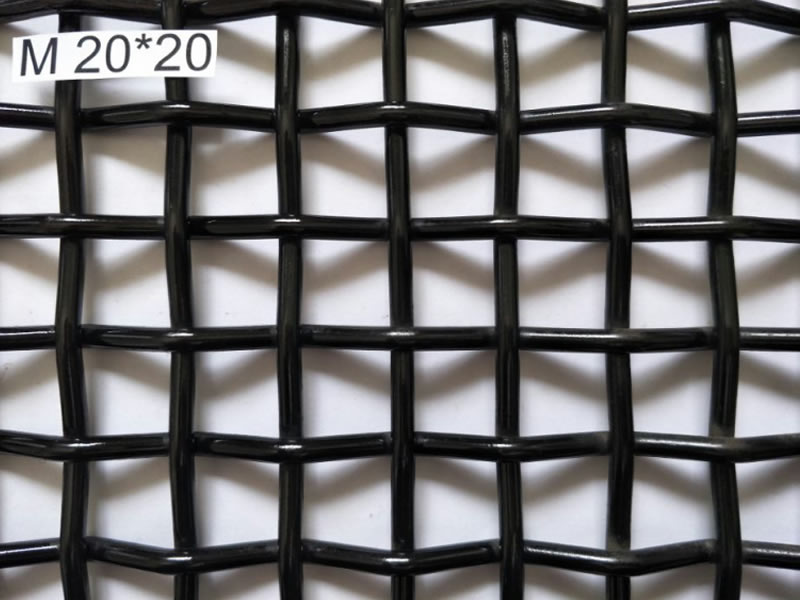

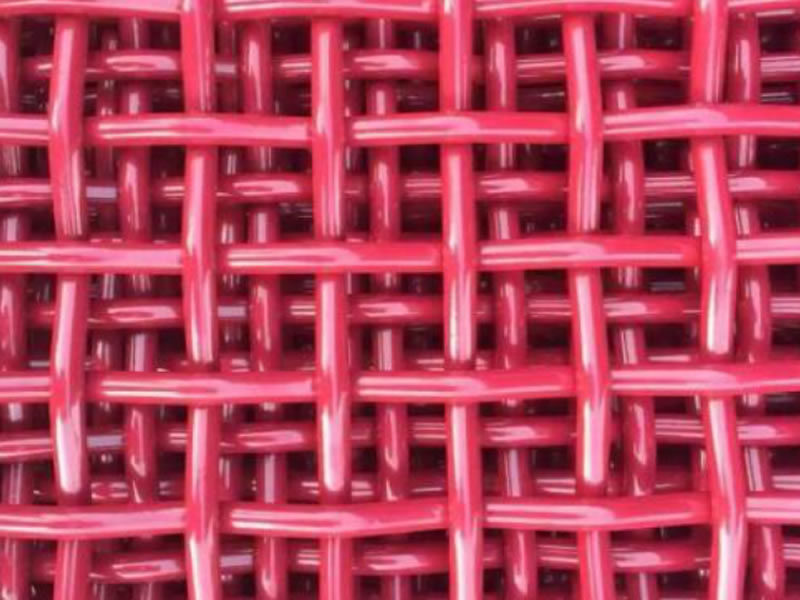

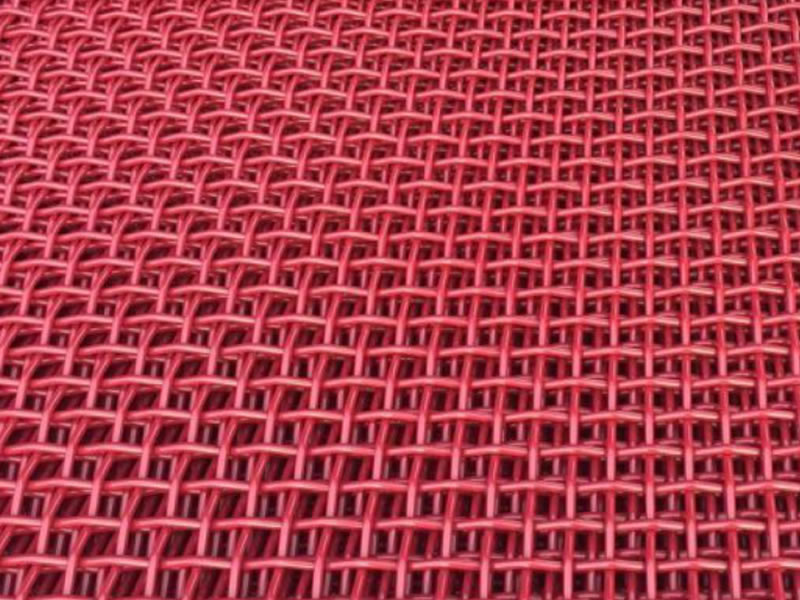

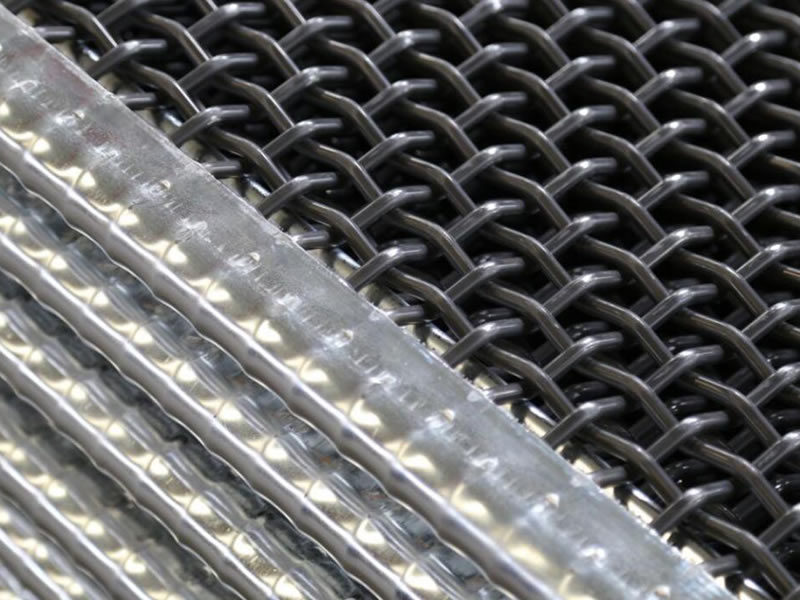

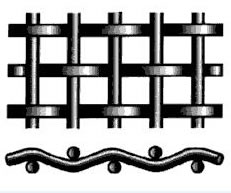

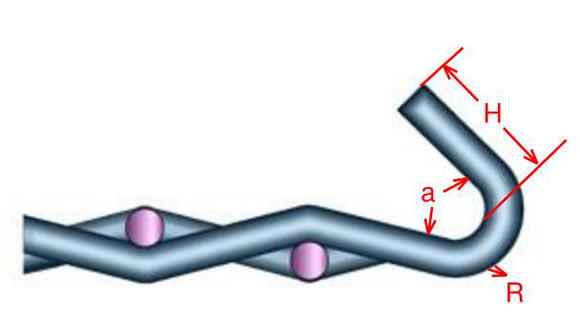

Double crimped type is usually named plain weaving. Both the warp wire and weft wire are woven directly by straight wire. It is rigid construction by evenly crimp in warp and weft wire.The wire are under crimped and sprung together so giving a tight mesh. It is optimum bending strength and excellent stability.

Double Woven Wire Screen Material: carbon steel wire,high spring steel wire, manganese steel wire and stainless steel wire(304,316).

Double Woven Wire Screen hole size: 2.0 - 80.0 mm

Double Woven Wire Screen Wire diameter: 0.8 - 10 mm

Double Woven Wire Screen dimensions: as required by customer, in rolls or formats

Installation instructions:

The screen is installed with using of tensioning metallic bars into a separator over different types of hook strips, further with using of side bars and wedges, possibly is fastened into a frame.

Double Woven Wire Screen Features:

Optimum bending strength

Varied lengths

Require less maintenance

excellent stability.

Applications:

High tensile screen cloth is commonly used in heavy duty applications for scalping and sizing of rocks,aggregates,limestone,etc.

They are weaved in sizes to suite most vibrating screens and available in:

* High Tensile Steel---Abrasion resistance

* Stainless Steel---Corrosion resistance

* Monel,Brass,etc---General applications

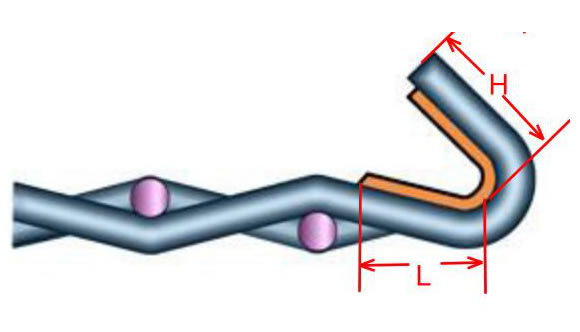

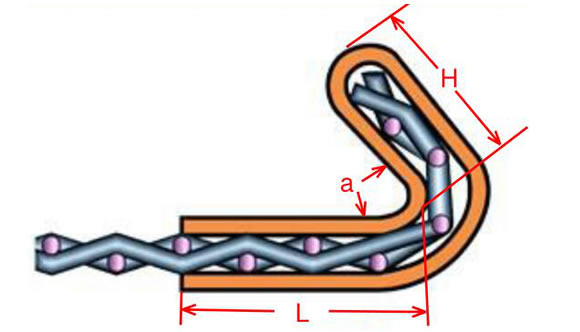

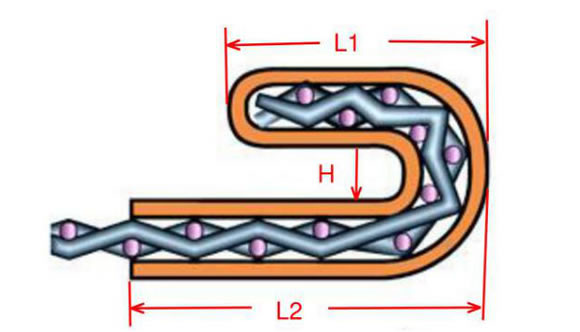

Hook Types:

End Tension Reinforced Shroud Banded Edge

Specially reinforced to prevent pull-out under extreme screen tensioning. Also available in Double Reinforced Style. Plate thickness can be required.

Packing:

Double woven wire screen is packed Inside with moisture-proof paper and other materials which doesn't affect the quality of product's surface,outside with wooden cases or wooden pallets.